Name:Bruce

Tel:+86 13657177611

E-mail:tona@tnfrp.net

Address:Near Juan Qiao village, Provincial Road 107, Dangyang city, Yichang City, Hubei Province

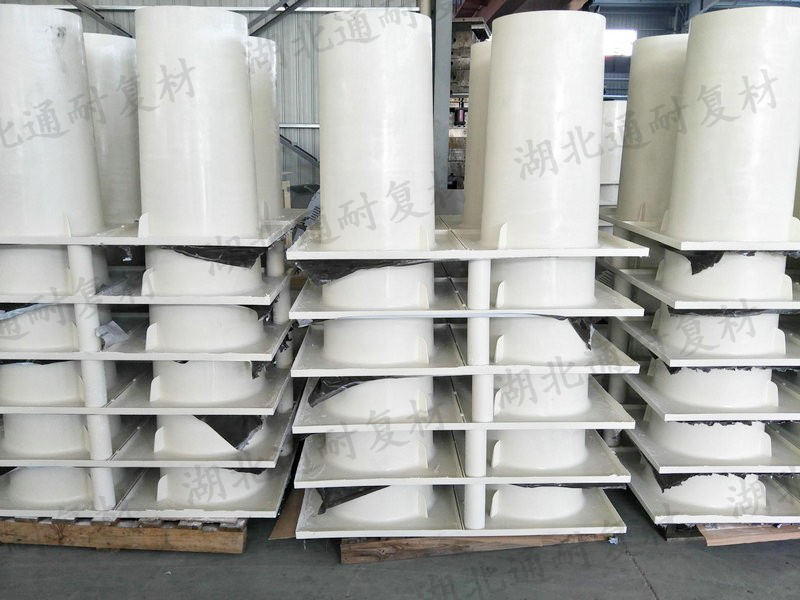

SMC Waffle Board/Tube Product Introduction

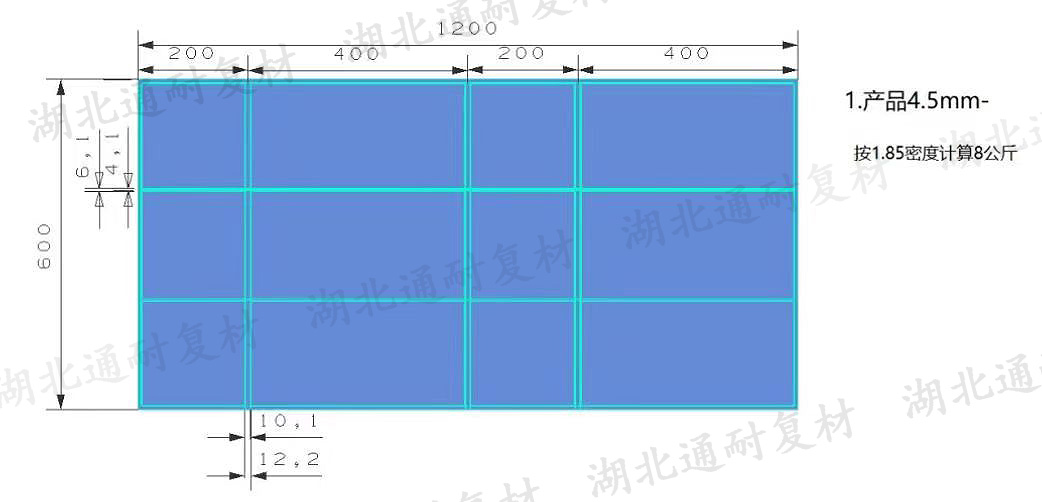

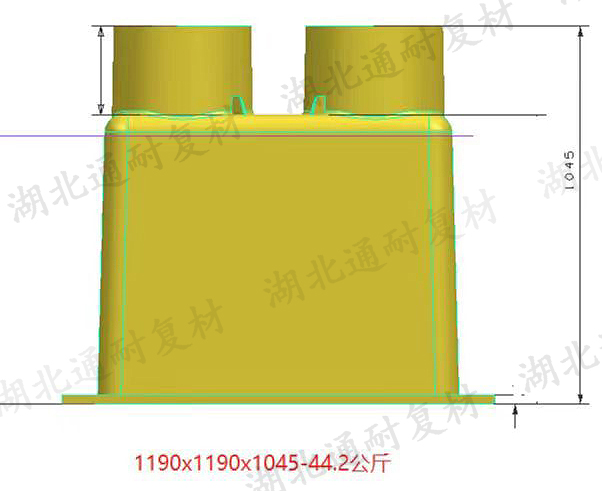

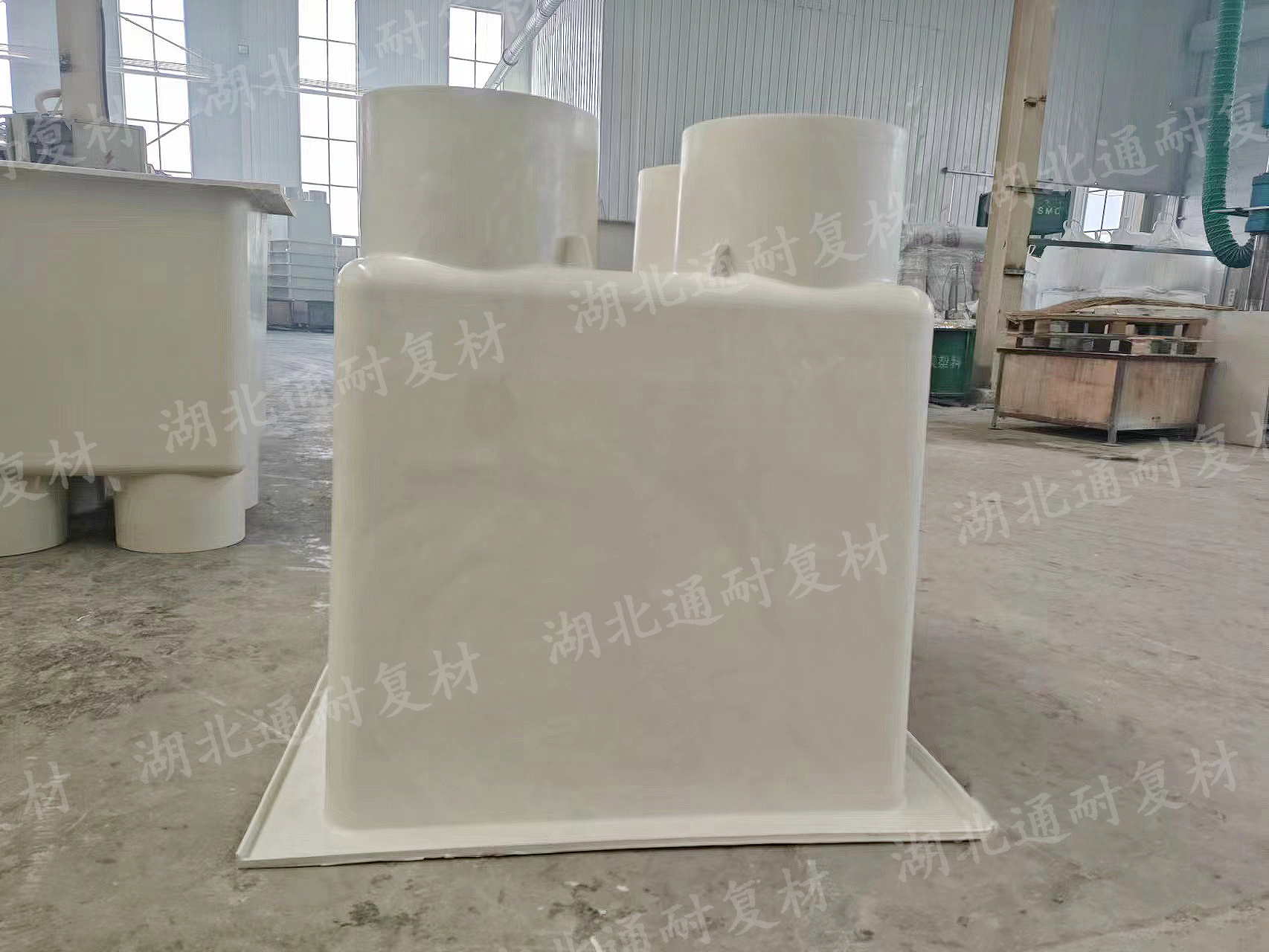

SMC waffle board/cylinder is a steel concrete structure made of epoxy fiberglass as a template, which is poured and compacted. After pouring, the template serves as the bottom template and is not removed to meet the cleanliness requirements of general electronic factories. The process involves placing a certain amount of molded plastic into a metal pair mold, and under a certain temperature and pressure, the molded plastic is heated and plasticized inside the mold, flowing under pressure, and filling the mold cavity to form and solidify the product.

SMC waffle board/tube, as a structural material, is widely used in clean areas of buildings with high requirements for cleanliness, such as electronic factories, precision instrument factories, clean operating rooms, etc. Because it can ensure the circulation and circulation of air, allowing particles suspended in the air to enter the upper space through the holes between the waffle plates and be centrally processed. But in order to improve certain performance, directional SMC waffle boards can also be produced, suitable for the construction, transportation, and packaging industries.

SMC Waffle Board/Tube Product Advantages

1. Using SMC waffle boards as templates can ensure accurate hole generation, high board flatness, and excellent flatness. The bottom edge and wall of the holes can immediately serve as decorative design layers.

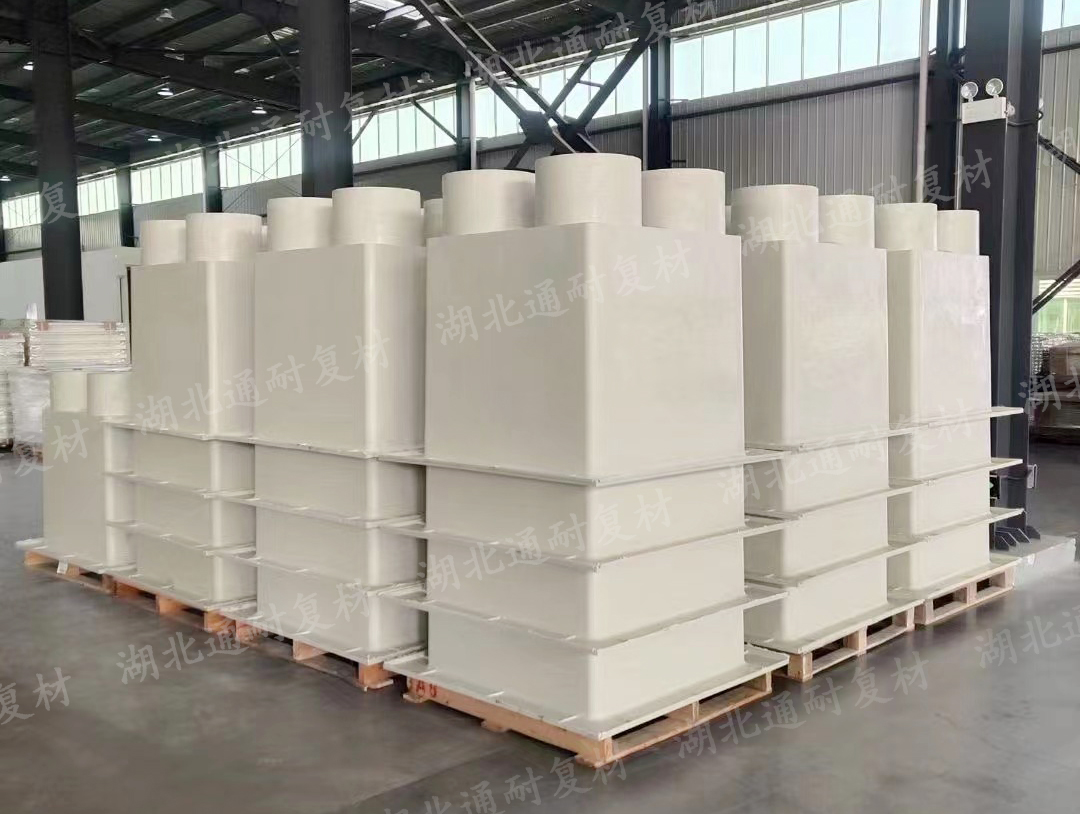

2. It is produced and processed in a processing plant and can be immediately installed on the construction site. Easy installation, simple and practical operation. Construction speed is faster and more reliable.

3. Choosing SMC waffle board to replace the epoxy resin ceiling building coating required for the purification workshop not only saves raw materials but also saves construction time for the epoxy resin ceiling.

4. The SMC Waffle board solves the problems of large plate thickness, self weight of the bottom plate, and concentrated hole spacing.

5. The appearance and construction quality have significantly improved. After the project construction, using the roof as the base, common product quality issues such as cracking, peeling, and exposure of general concrete structure roofs were eliminated, saving costs. And the cost of maintenance and post maintenance, with excellent appearance.

Manufacturer's strength

Hubei Tongnai Composite Material Technology Co., Ltd. is a high-tech enterprise that integrates the research and development, production, sales, and after-sales of SMC composite materials. The company is located in the Economic and Technological Development Zone of Dangyang City, Yichang City, Hubei Province, covering an area of 82 acres. There are three modern factory buildings, with 48 hydraulic presses, 1 4000T hydraulic press, 2 2500T hydraulic presses, 4 2000T hydraulic presses, 3 1500T hydraulic presses, and 2 1250T hydraulic presses, Three 1000T hydraulic presses, one 800T hydraulic press, four 630T hydraulic presses, 28 315T hydraulic presses, and over 200 sets of molding molds. The main product is SMC molding and processing. The company has established long-term cooperative relationships with many well-known domestic enterprises, and SMC raw materials are provided by top domestic partners to meet customers' needs for various high-performance composite materials. We provide comprehensive services from raw material selection, product design, mold manufacturing to product processing, logistics and transportation.

The company has a scientific, rational, united, and sincere team with a complete production management system, technical management system, quality management system, health management system, environmental management system, etc.

Company development philosophy: Technological innovation, never stop!

The company's core values: customer first, quality first, and service first.